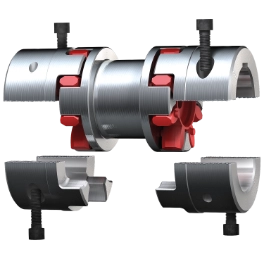

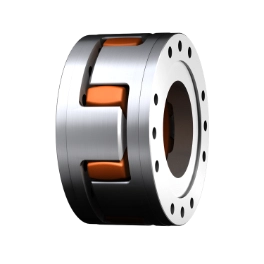

ROTEX® ZRS

0 - 520 Nm / torsionally flexible intermediate shaft coupling with SPLIT hubs or half shell hubs

ROTEX ZRS jaw coupling for bridging smaller and bigger shaft distances

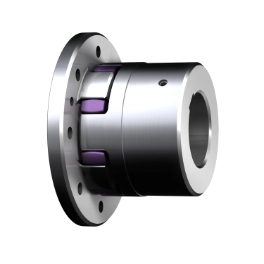

The lightweight ZRS made of high-strength aluminium captivates by a very high overall stiffness.

The high stiffness of the aluminium pipe arises from the structure consisting of two pipes that are connected via webs - the ROTEX cams.

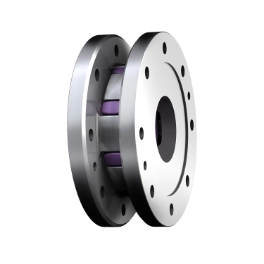

The critical bending speed of the coupling is positively affected; shaft distances up to 4,000 mm can be bridged subject to the very low bending.

In addition the speed referring to the shaft distance dimension can be significantly higher than with the renowned intermediate pipe coupling with steel pipe.

The high stiffness of the pipe allows for torque transmission from the soft 92 ShA spider to the torsionally stiff 64 ShD spider.

Fields of application of the torsionally flexible ROTEX ZR-S intermediate pipe coupling:

The ZRS intermediate pipe coupling is used wherever large shaft distances must be bridged, e. g. on scissors lifts and conveyor systems in the lower torque range.

The wide range of ROTEX hubs can be combined with the ZRS pipe. For example in combination with the split ROTEX-SH-SPLIT hubs they allow for radial assemby and disassembly without displacing driving and driven side.

Please note: This type is not permissible for crane and hoist drives.

Propriétés

double-cardanic jaw coupling with half shells (half shell coupling) and intermediate shaft (cardan shaft)

lightweight made of high-strength aluminium convinces by a very high overall stiffness.

for bridging large shaft distances

good damping properties due to double arrangement of spiders

intermediate pipe radially dismountable with flexible bearing in the GS spider

Détails sur le produit

Dessins CAO

Vous trouverez ici des dessins CAO 2D à télécharger.

Vous avez besoin de dessins 3D à la place ? Alors visitez notre bibliothèque CAO 3D.